Quality Measures

Armin Caps prides itself on providing its customers with the highest quality product all year round. Despite production at 24 hours a day 7 times a week with the highest levels of efficiency, Armin Caps has integrated several inspection levels which our closures must pass through to be packed up and ready to deliver.

After the primary stage of production in which the PE or PP material has been injected then moulded, with an ultra-speed camera every single closure is pictured in real time through an inferred lens to inspect the required dimensions and informalities it might have to be separated from the line.

After the first filter process the caps are dispensed and followed through sorting technology which lev- els the temperature of the closures sanitising the production.

The third filter of the production is another integrated inferred camera which inspects informalities such as dimensions and closure colour set for that specific production, if the cap does not meet the requirement within the slitting process camera, again the cap is rejected off the production line. The closures are then passed through another sanitation stage of low and high temperature which clearly sanitises the production.

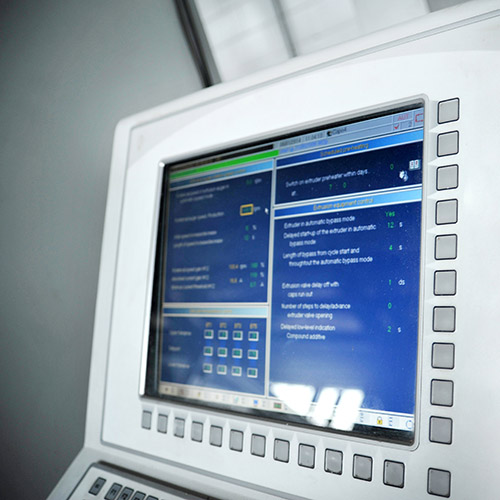

Throughout the whole production process several highly experienced Quality Control personal carry out several routine procedures to test the material through further stages of evaluation to confirm the required levels are maintained, which over 20 years of experience helps tick the boxes.

Standards

Armin Caps prides itself on holding and maintaining high industry global standards.